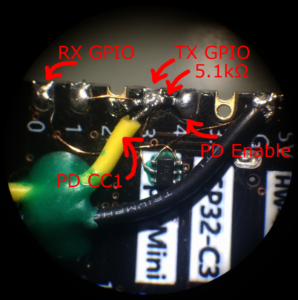

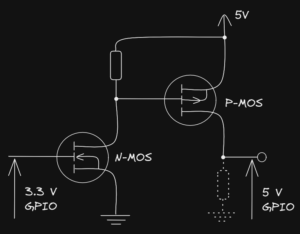

[ESP32-PD] USB PD using ESP32 / Zigbee Crib

Backstory So it was the end of the year again and everything got decorated for christmas. This time I got an extra job to “make the illumination of the crib properly”. Great, I had some cool COB LED strips waiting for a proper use case,...

Flipper Zero got ISO15693 (NFC-V) support

Some time ago, I blogged about my work on Flipper Zero support for Toniebox figurine. It took a while to get it through, but finally the Flipper Zero Dev team accepted my pull request for the ISO15693 emulation. Why is this such a big deal?...

ISO15693 Block for AARONIA RTSA-Suite

As you might have realized, I use an Spectran V6 for my RF stuff and am absolutely happy with this unique device, not only because of it’s compact form factor or amazing looks. Also the software is absolutely great with a lot of decoders and...

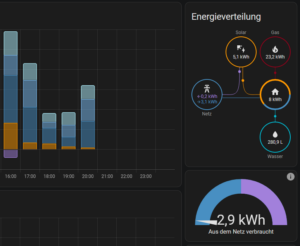

Emporia Vue 2 Custom Firmware

About a year ago, I found myself on the hunt for energy meters compatible with my power distribution box and stumbled upon Vue 2 by Emporia Energy. This device, with its support for three primary phases and 16 individual subnets, intrigued me. One of its...

ESP32 / Kenwood XS8/SL16 Remote

This is just a quite short and incomplete article, compared to the previous ones. On a rainy sunday afternoon I wondered if our audio receiver, a Kenwood KRF-V 7060, has some serial protocol which allows me to remote control the receiver via home assistant. I...

Toniebox Bluetooth Modification

Imagine your child has a toniebox and they are very happy with it. You see them dancing to the music all day. That’s great, right? But sometimes you wish the box could work with headphones. Oh, it does? That’s cool! But wait, is this a...

Flipper Zero for Toniebox figurines

When I first read about the Flipper Zero, I was intrigued to back the kickstarter campaign. But all that description text, videos and graphics looked far too good to be true. Two years later I found that the Flipper was not another kickstarter scam, but...

An IoT Geiger Counter

Building an ESP32 based geiger counter, for reporting radiation levels to a time series database, visualizing with grafana

Fuel Pressure Gauge for an Oldtimer

Some day a close relative contacted me and told me about a problem with his Porsche 911F Targa, built in 1971 and laboriously restored over the course of a few years. It is a great car, but when driving longer distances, the engine sometimes suddenly...

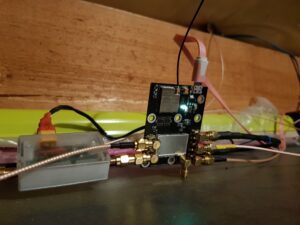

An ESP32 based RF antenna matrix

Playing around with SDRs for more than 14 years now, I learnt a lot. Not on a very professional level, but on a hobbyist niveau.I went through developing some firmware for the CY7C68013A, a framework for transferring IQ data from SDRs to processing modules, implemented...