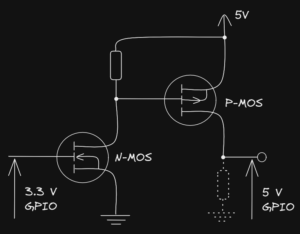

ESP32 / Kenwood XS8/SL16 Remote

This is just a quite short and incomplete article, compared to the previous ones. On a rainy sunday afternoon I wondered if our audio receiver, a Kenwood KRF-V 7060, has some serial protocol which allows me to remote control the receiver via home assistant. I...

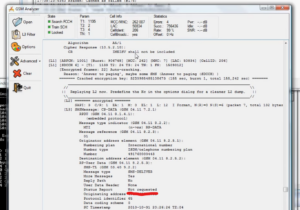

GSM Analyzer – Support for Aaronia RTSA / Spectran V6

Before I go into GSM Analyzer details a few words regarding the hardware. I was using various SDR devices in the last years. Started using specialized hardware named USB-RX a friend designed and also HiQ-SDR, RTL dongles etc. The most mature one was the USB-RX...

[blog] revived again

Its holiday time and i thought it’s time to revive this old blog and update some stuff. Let’s see how far this intent will come ;)

[EOS] TimerGen Tool

Since last year I helped a little developing Magic Lantern, a Firmware mod for Canon EOS DSLRs. I reverse engineered some interesting registers and memory structures that make frame rate patching possible. (yeah, as always I couldn’t resist reverse engineering the next device I bought...

[GSM] Kraken-win32

I added Kraken-win32 to my projects page. There you can read more about my kraken port.

WebDAVServer

I added a new project – my WebDAVServer for mobile phones. It was designed to be a small and simple WebDAV server for downloading files from your PC with your mobile phone. See the project page.

[ARMada] bugfix release

I fixed the totally crappy and hackish BL calculation routine. Now it should work fine for all types of jumps forward and backward. No idea why i never realized its bugs (?)

[ARMada] small updates

there are small updates to ARMada. let me cite the SVN log: Revision: 3585 Author: geggo Date: 19:55:28, Mittwoch, 19. August 2009 Message: fixed parameter limit check for ADD SP, val operation —- Modified : /trunk/nokia/ARMada/compiler.c Revision: 3579 Author: geggo Date: 19:29:51, Mittwoch, 19. August...

[GSM] New FFT Visualizer Component

This time I built a new FFT Visualizer Component. It’s a split “FFT Plot”+”Waterfall” view, which has the “FFT Plot” in the top and the waterfall in the bottom half. In the video (watch fullscreen in HD mode) you cannot see the dB markers very...